What information should I provide to make an oil seal suitable for me?

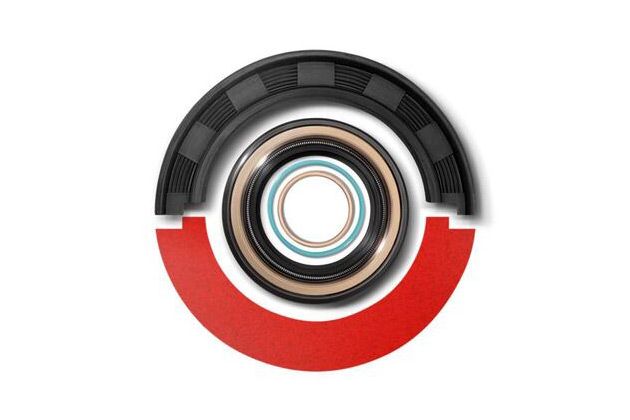

The manufacture of oil seals needs to pay attention to the application, material, hardness, size, and drawing.

NIYOK can produce products with a maximum size of 580 mm x 600 mm. In addition to customized application and hardness, we can do post-processing for oil seals, such as adhesive bonding, stamping, surface printing, designated packaging, and bonding with metal, Textile fabrics, PTFE / Teflon and other composite materials can be processed and formed at one time.

NIYOK has 40 years of great processing experience, and perform quality control strictly, also the factory has strict tests on raw materials, such as the use of Rheometer to test Rubber material, sulfur analyzer for rubber parameter inspection, and use Coordinate Measuring to measure dimension, Tensile Tester to test tensile of rubber sheets, Microscope to check tiny flaw of appearance, and Endurance Tester of Oil Seals is used to perform oil seal durability testing to meet customer needs. Therefore, our factory and products comply with ISO 9001 and IATF 16949 quality certification.

For new customers, we will charge a sample fee; however, we will refund it to you after the order is officially placed.

If you need professional services and consultation, please contact us for further analysis and research.